Features and advantages:

Efficiency:

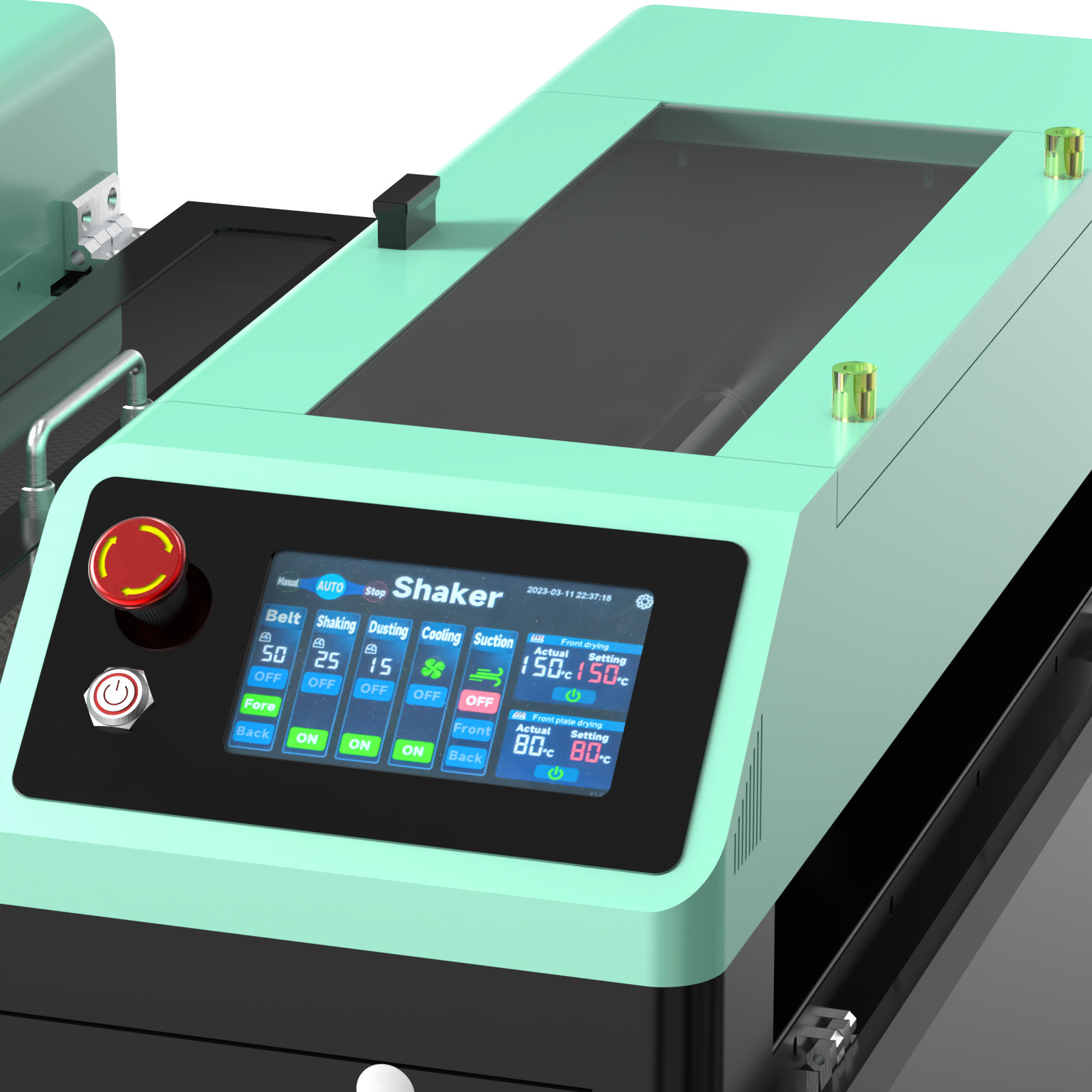

The DTF powder shaker can achieve fast and continuous powder spreading, shaking and drying processes, significantly improving production efficiency.

Accuracy:

Through the precise powder spreading device and vibration powder shaking system, the powder is evenly spread and the excess is accurately removed, improving the clarity and color saturation of the pattern.

Flexibility:

It is suitable for fabrics of various materials and sizes and patterns of different sizes and shapes. Whether it is a small batch trial production or large-scale production, it can meet the needs.

Ease of operation:

The DTF powder shaker adopts an advanced control system and human-machine interface design, making the operation easier and more intuitive. Operators only need simple training to get started.

DTF powder shaking machine is an efficient, accurate, environmentally friendly and flexible digital transfer equipment. It plays an important role in the clothing and textile industry, providing strong support for personalized customization, small batch production and rapid proofing.

Improve product quality:

Through precise powdering and drying processes, the DTF powder shaker can ensure that the color of the pattern is full, bright and long-lasting. The close combination of powder and fabric makes the pattern more wear-resistant, washable, and less likely to fade or peel, thus improving the overall quality and service life of the product.

Drying and fixation:

The powder attached to the pattern is dried and solidified by heating. This process helps bind the powder tightly to the fabric, making the pattern stronger and more washable.

High-temperature drying also enhances the vividness and gloss of the pattern, making the final product more attractive.

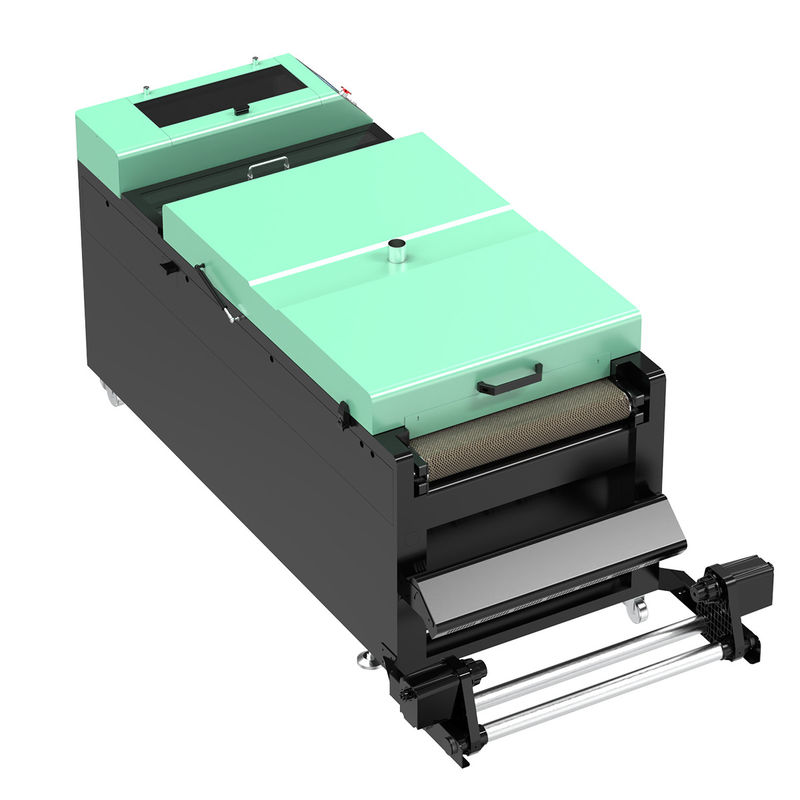

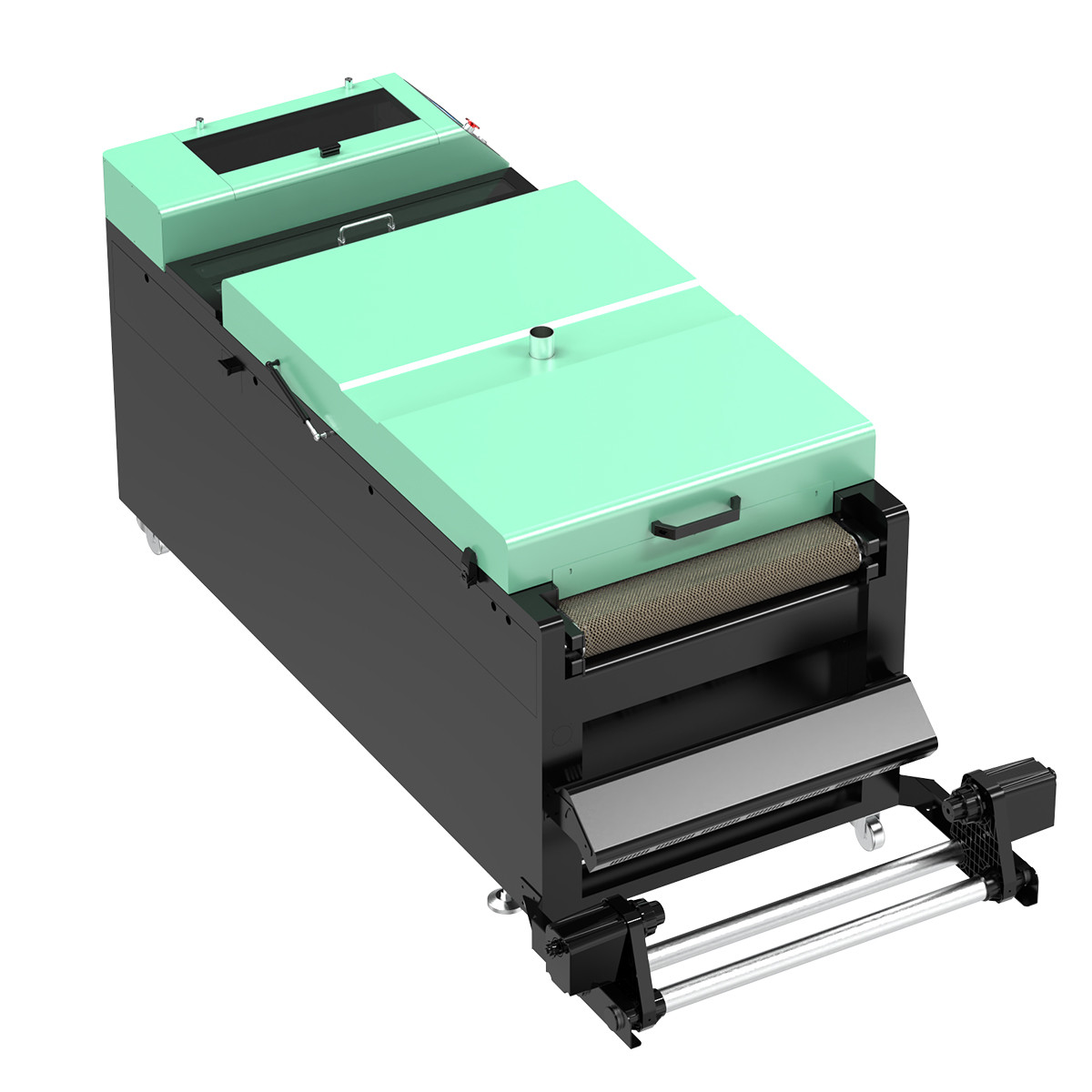

Machine Features:

- 60cm film width

- Touch smart control screen

- Two-stage heating, effective color fixation

- International brand Schneider electrical components,durable and stable

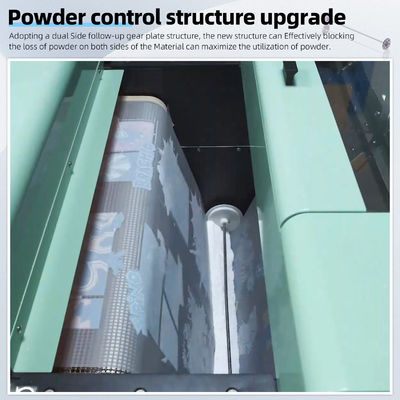

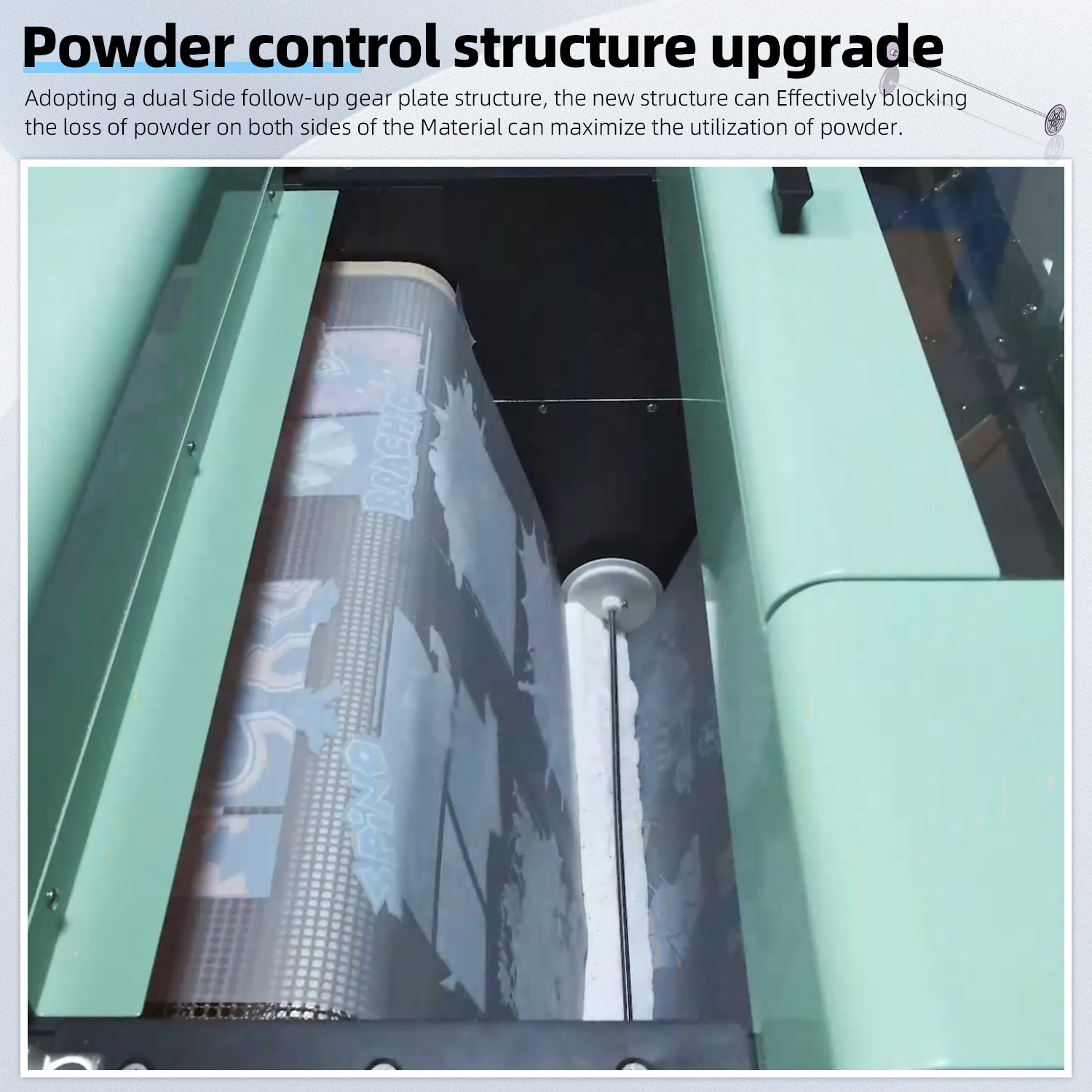

- Patented powder blocker,making full use of powder

- Automatic synchronized material collection system

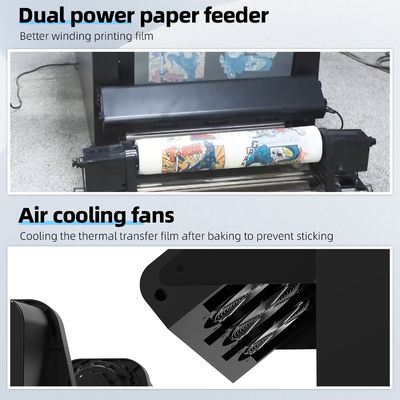

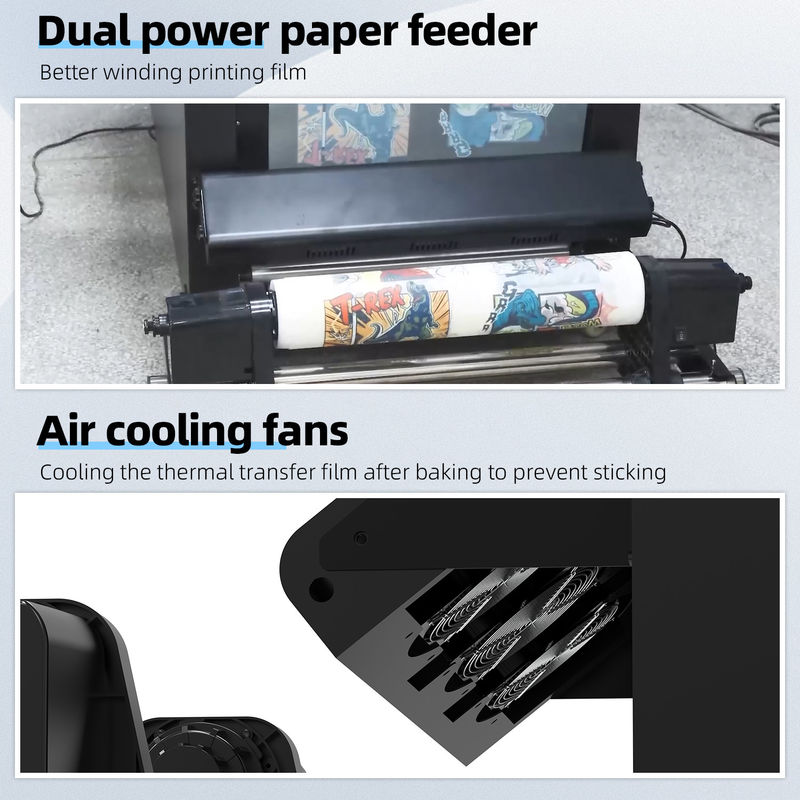

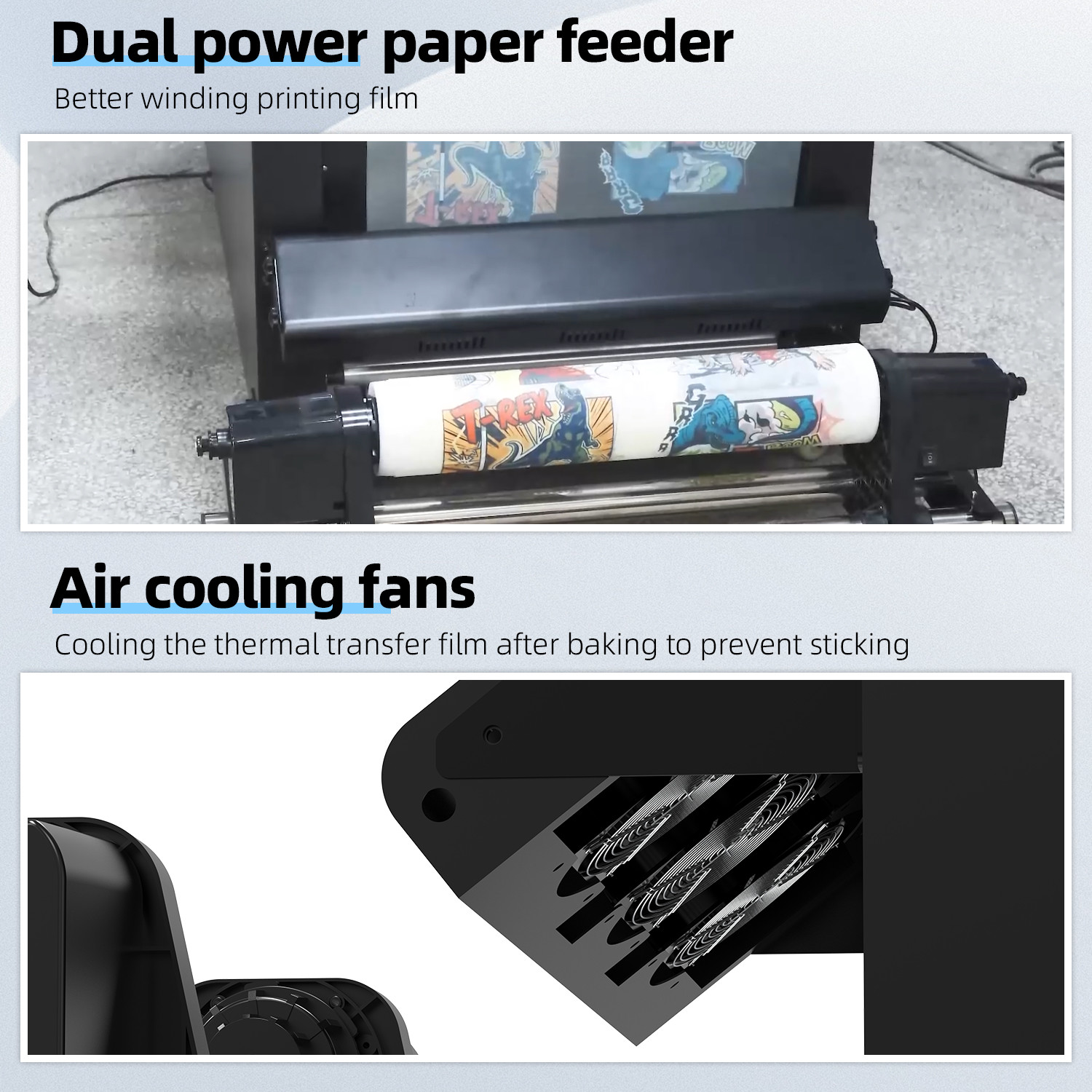

- Dual power paper receiver

- Upper drying curing

- Front quicle heating

- Air cooling fans

- Belt conveyor

- Extended baking tunnel, more uniform heating and better color fixation

|

Print width

|

≤60cm

|

|

Printing media

|

Nylon, chemical fiber, cotton, leather, swimwear, wetsuit, PVC, EVA, etc.

|

|

Rated power

|

6.5KW

|

|

Rated voltage

|

220V 30A

|

|

Temperature & Humidity

|

15-30℃ & 35-65%

|

|

|

Machine 2291*912*998mm 250kg

Packing 2100*1130*1113mm 300kg

|

After-sales service:

We provide a series of services such as 1-on-1 video installation and subsequent machine maintenance.

CAUTION:

When handling DTF Hot Melt Powder, do not ingest or inhale the powder. Harmful if swallowed. Skin irritation may occur. Avoid contact with skin and eyes. In case of contact with eyes, rinse with plenty of water. Wear protective clothing, equipment, mask and gloves when handling powder. If allergic reaction persists or if ingested accidentally, seek medical help immediately.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!